Ensuring Reliable Power - Critical Care

Facing growing risks from an aging boiler system that caused power instability and potential threats to patient safety. In response, the hospital replaced four outdated plants with a centralized, state-of-the-art Central Utility Plant (CUP). RoviSys delivered two integrated systems that control the 13.4 kV power system, turbine, and diesel generators.

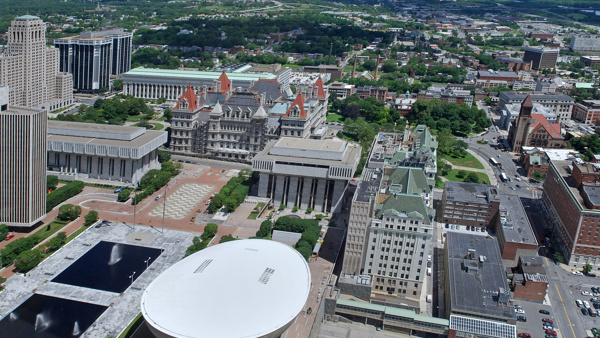

Revolutionizing Emergency Power at NY Empire State Plaza

In the sprawling landscape of government infrastructure, reliability is not just a goal—it’s a mandate. A New York state government campus turned to RoviSys to redefine emergency power capabilities for office buildings, a performing arts center, and the NY Governor’s Mansion.

Integrating Siemens PCS7 to Advance Manufacturing

This advanced hot-rolling and processing facility (HRPF) built in Brackenridge, Pennsylvania is part of Specialty Rolled Products operations, and manufactures nickel-based alloys, titanium, specialty alloys, zirconium, and stainless-steel sheet and plate. It's among the largest, most powerful hot-rolling facilities in the world.

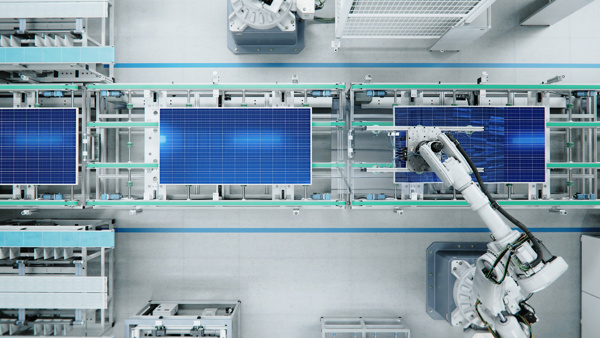

Empowering Innovation, One Panel At A Time

To keep up with global demand for solar energy, a leading manufacturer of photovoltaic panels needed to modernize its production facility in Southeast Asia.

A Path to Paperless: Navigating The Biopharma MES Journey

A paradigm shift towards paperless systems is well underway in biopharmaceutical manufacturing, and this industry leader needed a partner to help upgrade systems in order to go paperless. RoviSys enabled seamless connections to Historian, MES, and related systems.

Fulfilling Data Integrity Gaps with Digitalization

Data integrity, a crucial aspect of Life Science manufacturing, is driving companies to upgrade their existing systems. Leaders in the industry are upgrading facilities and improving systems in an effort to go paperless and reduce human error. RoviSys is enabling this transformation.

Improving Cybersecurity Resilience and Operational Visibility

The adoption of Industry 4.0 involves the transforming the shop floor and integrating digital technology. This evolution increases operational efficiency, but introduces vulnerabilities and risk of cyberattacks. Leadership at this pharma giant turned to RoviSys to safeguard their future.

Harnessing The Potential of Fault Detection and Diagnostics To Maximize Uptime

Abbott, a global leader in nutrition and health product R&D, and innovation turned to RoviSys Building Technologies for process analytics that deliver efficiency improvements and cost reduction.

Refining the Ingredients for Automation Success

To reap the full benefits of Industry 4.0 technologies, this global supplier of agricultural commodities needed to overhaul the outdated control infrastructure at one of its U.S. facilities. The company also aimed to develop a template that could be replicated at its other sites throughout North America.

Trailblazing the Future of Semiconductor Manufacturing

In response to ever-increasing global demand, a leading global semiconductor manufacturer significantly expanded production capacity in Southeast Asia. RoviSys integrated the Facility Management Control System (FMCS) and played a key role getting the new fab plant up and running in record time.

Accelerating The Next Revolution In Medicine

To bridge the gap between research and commercialization of cell-based therapies, a leading university and global solutions provider teamed up to build and operate a state-of-the-art innovation center. Proven experience supporting life-sciences manufacturing positioned RoviSys Building Technologies (RBT) in a key role in the project execution.

Automaker Turns to RoviSys for Facility Retrofits

This U.S. automaker was paying a steep price for out-of-date HVAC and building control systems in its legacy facilities – and the maintenance contracts that came with them. To control costs and boost operator comfort and safety, a technology refresh was needed.

Fast Tracking A Vaccine For COVID-19

This global leader in pharma planned to repurpose existing manufacturing space at its Michigan facility, as part of the production ramp-up needed to meet COVID-19 vaccine demand regionally and globally.

Embracing A Plant-Based Future

A global food & beverage conglomerate needed additional production capacity at a Northeast Ohio facility. Navigating project complexities required a trusted integration partner with industry-specific expertise in building automation.

Greener Commerce: Flipping The Script On Data Centers

After opening a new state-of-the-art data center on its campus in 2017, the company realized a need to update two existing facilities on the same campus. A unified control architecture, a common software platform and new hardware. The company needed a partner with a unique mix of experience, resources and qualifications.

Positioning A Paper Mill For Sustainable Success

To revitalize one of its legacy U.S. paper mills, this global provider of paper and packaging solutions needed to give the facility a high-tech makeover. RoviSys delivered solutions that immediately impacted the company’s top and bottom lines.

Taking Waste Out Of The System

The Northeast Ohio Sewer District, the largest wastewater-treatment provider in the State of Ohio, needed a streamlined process-control system to improve efficiency, reduce engineering costs, and simplify training.

Design-Assist Seals The Deal: A Smart Partnership In Specialty Chemicals

In order to meet COVID-fueled demand for its coatings and sealants, the company needed to build a new production facility, and capitalize on an unprecedented interest in home-renovation projects.

Driving Efficiency In Biotech Operations

To provide innovative technologies and solutions for its biotech customers, this skid manufacturer needed a modular process skid that would allow operations to quickly toggle between two key processes within the same system.

Going With The Flow: Custom Integration Solution Brings New Pipeline Online – Fast

This U.S.-based oil producer with midstream operations on the Gulf Coast needed a quick-to-market control-systems solution to integrate a new pipeline into its existing infrastructure – with minimal disruption to operations.

Making the Grade: Driving Energy Insights and Efficiency Across Campus

This community college system needed real time data on energy consumption and improvement options. First, it needed a uniform software platform to provide critical dashboarding and analytics.

Rebuilding A Legacy: Uptime, Safety, & Sustainability

Big Three automaker operates in aging, 20th century facilities that rely on legacy building control systems that have run far beyond their useful lives. The systems need an update—but without disrupting production.

Inking A Digital Revolution

An industry-leading printer ink manufacturer still relied on manual paper logs to track consumption and movement of over 100 raw materials. To maximize efficiency and reduce human error, the plant needed a digital makeover.

Fueling The Semiconductor Industry With Real-Time Intelligence

An equipment maker at the front-line of the semiconductor demand surge harnessed real-time material data to improve consistency and reduce errors.

Taking Clean Rooms To The Next Level

A modular cleanroom manufacturer is out to disrupt the market, delivering traceable, automated condition monitoring in every installation around the world. Partnering with RoviSys Building Technologies made it possible.

Packaging Data Consistency

RoviSys was able to focus on using the out of the box functionality of the PI System. New reports enabled operators to intelligently adjust production and OEE targets and helped increase uptime by nearly 30%.

Giving Old Machines a Smart Upgrade

Unscheduled downtime of legacy production equipment in this medical device plant was causing major productivity declines. With no option for equipment upgrades, the plant needed a new system capable of delivering the deep diagnostics necessary to keep production moving.

A Digital Transformation For The Oil & Gas Industry

For the first time, the oil refiner has access to real-time inventory that is traceable and auditable all the way through the process.

Automating Process Perfection

For this around-the-clock glass manufacturer, aging hardware, lack of integration support and system robustness issues threatened the overall throughput of the plants operation. It’s time for an automation upgrade.

A Custom Solution For High Volume Challenges

From dashboards to machine learning: In order to improve quality,

throughput, and availability in its high-volume facility, this distribution

center required a custom solution that could efficiently move and

track material through its ever-shifting logistical puzzle.

Brewing Up A Data Storm

The company quickly identified inconsistencies among its breweries and detected previously unnoticed power and water usage irregularities that were affecting both productivity, efficiency, and cost at each site. Each 1% improvement resulted in millions of gallons of process water savings.

Food & Beverage Manufacturer Goes Digital on Quality

Substantial expertise in process automation allowed RoviSys to suggest changes to the company’s business processes and control systems instrumentation that simplified process and tracking complications and directly met their needs.

Tracking Quality, Efficiency & Waste In The Pharmaceutical Industry

The company resolved it's fundamental issues, and is now able to fully track quality, quickly identify defects, and to pinpoint defect causes in the robust, real-time manner the industry demands.

Going Big To Reduce Scrap & Risk

U.S. Based plastic bag manufacturer partners with RoviSys for a legacy controls and information infrastructure upgrade. The result: A state-of-the-art, data-rich system that was up to the challenge of modern manufacturing.

Powering The Future

St. Joseph's generates their own power now, improving reliability, reducing greenhouse gas emissions by 11,676 tons/year, and reducing the annual utility budget. Approximately $1 million reduction in its first full year of operation.

Microgrid Controls End Campus Blackouts - Union College

Switching to this tightly controlled and monitored microgrid system, Union college was able to end frequent blackouts and provide students, faculty, and essential research facilities the stable power source they required.

Preserving Power on Campus - University of Michigan

When UofM operations teams became aware that the central power plant and sub-stations weren’t equipped to handle harsh weather events or utility outages adequately, an upgrade was needed.

A Preventative Plan to Maximize Instrument Uptime

Unplanned repairs dropped from 337 to just 46 per year—a massive 86% reduction. In the process, plant availability was increased by 42%. Management has gained annual budgeting and forecasting insights based on asset maintenance estimates and plans to expand the program to other areas of their treatment facilities based on this success.

NERC-CIP Assessment: Powering Up Cybersecurity

With a unique set of capabilities and expertise in the utilities industry plus a deep understanding of process controls, information technology and management, and cybersecurity, RoviSys was the clear choice to take on this project.

Sounding The Alarm

RoviSys was able to address both challenges with unique assets that other integrators couldn’t match: a pre-existing relationship with the manufacturer and extensive experience with the Rockwell Automation systems used to run existing operations.

Real Time Material Tracking For Parts Manufacturing

A U.S. based manufacturer needed a solution to display real time locations of assets and materials, and to provide historical records identifying quality issues and reasons for downtime.

Mixing Fast Implementation with Long-Term Growth

Facing furnace failure and an obsolete control system, this float glass manufacturer required a full system modernization in record time to meet its aggressive production goals.

Converting Waste Into Profit

When Magnus International Group purchased a shuttered specialty chemicals plant in 2007, the Cleveland-based startup saw it as an entry point into the oleochemicals market with the initial goal of converting natural fats and oils into industrial products.

Data Center Goes Green

This South Carolina data center is growing fast. Boosted by a strong reputation for reliability, efficiency, and low costs, the company has maxed out their space in eight buildings with water-cooled servers.

Upgrading Without Downtime in an Operational Datacenter

An outdated temperature control system risks raising the temperature for servers in this colocation data center. The challenge now is to upgrade the outdated automation system without raising them even further.

Taking Control of Drug Validation

An outdated control system was preventing this pharmaceutical manufacturer from bringing critical new drugs into production. To serve its market and its patients, the company needed to rebuild from the ground up.

Automating 80 Years of Success

Prompted by a rapid boom in the building and construction market, this construction adhesives manufacturer needed to modernize heavily manual manufacturing operations and transition to a state-of-the-art facility with automated solutions.

Updating Efficiency at Sea

With a propulsion system dating back to the 1940s, this commercial vessel was in dire need of a major upgrade to extend its life and reduce its emissions.